Showing 1–12 of 28 results

- SKU:MLLG-E-LED-EXPLA-80-50-[V]-C1D2 | Web ID:1541100V-277V:89 In StockShips 3-5 Days277V-480V:Built to Order 6 Weeks

- Watts: 80

- Lumens: 11200

- Lumens/Watt: 140

- Replaces: 250 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 10kV

- Operating Temp: -40°F to 140°F (-40°C to 60°C)

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Beam Angle (Opt): 40° | 60° | 90°

- Optics: Tempered Glass Lens

- Fixture Color: Gray

- Mount: Yoke | 3/4 in NPT Pendant

- Dimensions: 12.5 X 9.5 X 6.5 in

- Weight: 26 lbs

Starting At$490.57 - SKU:MLLG-E-LED-EXPLA-100-50-[V]-C1D2 | Web ID:1600100V-277V:387 In StockShips 3-5 Days277V-480V:50 In StockShips 3-5 Days

- Watts: 100

- Lumens: 14000

- Lumens/Watt: 140

- Replaces: 250 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 10kV

- Operating Temp: -40°F to 140°F (-40°C to 60°C)

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Beam Angle (Opt): 40° | 60° | 90°

- Optics: Tempered Glass Lens

- Fixture Color: Gray

- Mount: Yoke | 3/4 in NPT Pendant

- Dimensions: 12.5 X 9.5 X 6.5 in

- Weight: 26 lbs

Starting At$518.18 - SKU:MLLG-E-LED-EXPLA-150-50-[V]-C1D2 | Web ID:1518100V-277V:76 In StockShips 3-5 Days277V-480V:11 In StockShips 3-5 Days

- Watts: 150

- Lumens: 21000

- Lumens/Watt: 140

- Replaces: 400 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 10kV

- Operating Temp: -40°F to 140°F (-40°C to 60°C)

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Beam Angle (Opt): 40° | 60° | 90°

- Optics: Tempered Glass Lens

- Fixture Color: Gray

- Mount: Yoke | 3/4 in NPT Pendant

- Dimensions: 14.9 X 9.1 X 10.6 in

- Weight: 26 lbs

Starting At$584.91 - SKU:MLLG-LN-LED-EXPL-60-50-120-C1D2 | Web ID:1898Back in Stock 12/30

- Watts: 60

- Lumens: 7800

- Lumens/Watt: 130

- Replaces: 250 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- Voltage: 100V-277V

- Surge Protection: 4kV

- Operating Temp: -40°F to 131°F

- Rated Life: 50,000 (L70) hours

- Dimmable: No

- Beam Angle (Std): 120°

- Mount: Bracket | Surface | Wall

- Dimensions: 48.4 x 4.9 x 3.5

- Weight: 17 lbs

Starting At$545.45 - SKU:MLLG-LED-EXPLF2-40-50-C1D2-V2 | Web ID:2012Availability:195 In StockShips 3-5 Days

- Watts: 40

- Lumens: 5600

- Lumens/Watt: 140

- Replaces: 175 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- Voltage: 100V-277V

- Operating Temp: -40°F to 131°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Fixture Color: Gray

- Mount: Bracket | Surface | Wall

- Dimensions: 26.4 x 4.5 x 6.3

- Weight: 17 lbs

Starting At$387.27 - SKU:MLLG-LED-EXPLF4-60-50-C1D2 | Web ID:2013Availability:299 In StockShips 3-5 Days

- Watts: 60

- Lumens: 8400

- Lumens/Watt: 140

- Replaces: 250 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- Voltage: 100V-277V

- Operating Temp: -40°F to 131°F

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Fixture Color: Gray

- Mount: Bracket | Surface | Wall

- Dimensions: 50 x 4.5 x 6.3

- Weight: 30 lbs

Starting At$579.09 - SKU:MLLG-LED-EXPLF4-80-50-C1D2-V2 | Web ID:2014Availability:175 In StockShips 3-5 Days

- Watts: 80

- Lumens: 11200

- Lumens/Watt: 140

- Replaces: 250 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V

- Operating Temp: -40°F to 140°F (-40°C to 60°C)

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Fixture Color: Gray

- Mount: Bracket | Surface | Wall

- Dimensions: 47 x 4.7 x 9.5

- Weight: 20 lbs

Starting At$636.36 - SKU:MLLG-LED-EXPLR4-50-50-C1D2 | Web ID:1768Availability:67 In StockShips 3-5 Days

- Watts: 50

- Lumens: 7000

- Lumens/Watt: 140

- Replaces: 250 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V Optional

- Operating Temp: -40°F to 122°F (-40°C to 50°C)

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Optics: Polycarbonate Lens

- Mount: Chain-Cable | Surface

- Dimensions: 53 X 8.2 X 4.7 in

- Weight: 16 lbs

Starting At$644.83 - SKU:MLLG-LED-EXPLR4-60-50-C1D2 | Web ID:1833Availability:84 In StockShips 3-5 Days

- Watts: 60

- Lumens: 8400

- Lumens/Watt: 140

- Replaces: 250 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V Optional

- Operating Temp: -40°F to 122°F (-40°C to 50°C)

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Optics: Polycarbonate Lens

- Mount: Chain-Cable | Surface

- Dimensions: 53 8.2 X 4.7 in

- Weight: 16 lbs

Starting At$684.48 - SKU:MLLG-E-LED-EXPLH-60-50-[V]-C1D2 | Web ID:1605100V-277V:70 In StockShips 3-5 Days277V-480V:Built to Order 6 Weeks

- Watts: 60

- Lumens: 8400

- Lumens/Watt: 140

- Replaces: 250 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK08

- Voltage: 100V-277V | 277V-480V

- Operating Temp: -40°F to 140°F (-40°C to 60°C)

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Bracket | Surface | Wall | 3/4 in NPT Pendant

- Dimensions: 47 X 4.7 X 9.5 in

- Weight: 15 lbs

Starting At$663.46 - SKU:MLLG-E-LED-EXPLH-80-50-U-C1D2 | Web ID:2668Availability:16 In StockShips 3-5 Days

- Watts: 80

- Lumens: 11200

- Lumens/Watt: 140

- Replaces: 250 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK08

- Voltage: 100V-277V

- Operating Temp: -40°F to 140°F (-40°C to 60°C)

- Rated Life: 50,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Optics: Polycarbonate Lens

- Fixture Color: Gray

- Mount: Bracket | Surface | Wall | 3/4 in NPT Pendant

- Dimensions: 47 X 4.7 X 9.5 in

- Weight: 15 lbs

Starting At$733.60 80 Watt LED Paint Booth Fixture | 11200 Lumens | Class 1 Division 1 | 5000K | 100V-277V or 277V-480V

SKU:MLLG-E-LED-EXPLD-80-50-[V]-C1D1 | Web ID:1280100V-277V:22 In StockShips 3-5 Days277V-480V:Built to Order 6 Weeks- Watts: 80

- Lumens: 11200

- Lumens/Watt: 140

- Replaces: 250 Watt Metal Halide

- Color Temp: 5000K

- CRI: 70+

- IP Rating: IP66

- IK Rating: IK10

- Voltage: 100V-277V | 277V-480V

- Surge Protection: 10kV

- Operating Temp: -40°F to 140°F (-40°C to 60°C)

- Rated Life: 50,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 120°

- Beam Angle (Opt): 40° | 60° | 90°

- Optics: Tempered Glass Lens

- Fixture Color: Gray

- Mount: Yoke | 3/4 in NPT Pendant

- Dimensions: 11.6 X 11.6 X 9.57 in

- Weight: 27 lbs

Starting At$763.64

What are LED Paint Booth Lights?

LED light fixtures are explosion proof-rated systems engineered specifically for environments with airborne paint vapors and volatile organic compounds. Unlike standard industrial lighting, these units meet rigorous Class 1 Division 1 safety requirements to prevent ignition in hazardous atmospheres.

Our explosion proof LED lights deliver superior illumination while maintaining the safety certifications critical for spray painting operations. With integrated drivers that automatically adapt to your building's 120-277V or 277-480V electrical systems, installation connects seamlessly to existing circuits without additional transformers.

OSHA's guidance on workplace safety emphasizes the importance of proper lighting in hazardous environments where flammable vapors may be present. The National Electrical Code (NEC) Article 500 series provides detailed requirements for electrical equipment installation in classified locations, ensuring that fixtures meet appropriate explosion-proof standards to prevent ignition sources in potentially dangerous atmospheres.

What are the Benefits of Using LED Paint Booth Lights?

After 17 years of working with automotive shops and industrial painting facilities, we consistently see these advantages drive the decision to upgrade:

| Immediate Energy Reduction | Facilities typically cut lighting costs by 60–75% compared to metal halide systems. A 100W LED fixture replaces a 400W metal halide while delivering superior illumination. * |

| Extended Operating Life | LED systems commonly provide 10+ years of trouble-free performance, even under heavy daily use. This eliminates frequent bulb replacement cycles of 6–12 months found in traditional lighting. |

| Reduced Heat Generation | LED fixtures run significantly cooler than metal halide, reducing HVAC load and improving comfort in spray booths and paint preparation areas. |

| Flicker-Free Performance | Stable, flicker-free illumination eliminates the eye strain and headaches caused by fluorescent or HID strobing. Workers experience better concentration during detailed paint application. |

| Superior Color Accuracy | High CRI 80+ illumination delivers true color representation without the yellow tint associated with sodium vapor or metal halide. Essential for accurate color matching and paint quality control. |

| Minimal Maintenance Requirements | No ballasts, no bulbs, and no emergency repair cycles. Maintenance teams focus solely on simple lens cleaning rather than disruptive fixture failures. |

* DOE Energy Savings Validation: The U.S. Department of Energy confirms that modern LED systems can reduce energy consumption by 50–90% in industrial applications. Their LED lighting guidance highlights major efficiency gains compared to metal halide and HPS systems.

What are the Recommended Foot Candles for Paint Booths?

Proper illumination levels depend on the specific painting operations and quality requirements. Based on industry standards and our experience designing hundreds of booth layouts:

- General Automotive Painting: 50-80 foot candles

- Precision Detail Work: 80-150 foot candles

- Paint Inspection and Quality Control: 100-150 foot candles

For booths with 10-12 foot ceilings, we typically recommend fixtures with 90-120 degree beam angles to achieve uniform coverage. Higher ceilings benefit from narrower 60-90 degree beams to concentrate light at the work surface level. The length of your booth determines fixture spacing requirements.

The Illuminating Engineering Society provides detailed recommendations for workplace lighting levels across various industrial applications. The IES Lighting Handbook and recommended practices establish guidelines for illumination levels in different work environments, helping facility managers determine appropriate lighting levels for tasks requiring visual precision and color accuracy.

What is the Best Way to Choose the Right LED Paint Booth Lighting?

The critical first step involves confirming the hazardous area classification with your local fire marshal or AHJ (Authority Having Jurisdiction). Never substitute vapor-proof fixtures for explosion proof requirements, as this creates serious safety risks. Once you have confirmed the necessary safety rating, consider these factors. Booth dimensions determine fixture count and beam angle selection. Painting applications influence the required light levels and color temperature. Most customers prefer 5000K daylight for accurate color rendering, while some choose 4000K neutral white for warmer working conditions. Mounting options include pendant, surface mount, and pole mount configurations. Pendant mounting typically provides the most uniform light distribution, while surface mounting works well for lower ceiling applications. We offer a wide variety of mounting solutions.

What Classifications of Lighting Are Needed for LED Paint Booth Lights?

Always consult your local fire department or building inspector for definitive classification requirements. However, Class 1 Division 1 (C1D1) represents the safest approach for spray painting environments where explosive vapors are present during operation. C1D1 fixtures undergo more rigorous testing and certification processes, ensuring safe operation even when explosive concentrations exist. While Class 1 Division 2 (C1D2) fixtures cost less initially, the safety margin and compliance confidence of C1D1 typically justify the investment. For more detailed information on classifications, contact our team.

What's the Difference Between Class 1 Division 1 and Class 1 Division 2 in Paint Booth Lighting?

The distinction centers on when explosive conditions exist:

- Class 1 Division 1: Designed for locations where explosive vapor concentrations exist continuously or frequently during normal operations

- Class 1 Division 2: Intended for areas where explosive concentrations occur only during abnormal conditions or equipment failure

A critical consideration: Don't assume C1D2 applies simply because the booth operates intermittently. During active spraying, C1D1 conditions exist. We recommend approaching this decision with safety as the primary concern rather than initial cost savings. Consider wall-mounted options for optimal coverage.

Safety and Performance Certifications

All our fixtures carry essential certifications including DLC Premium, UL Listed, and ETL Listed approvals. These certifications ensure safety, performance, and energy efficiency while qualifying your project for utility rebates and tax incentives. DLC Premium certification guarantees the highest efficiency standards and maximum rebate eligibility. We also offer specialized panels and tubes for specific applications.

The Design Lights Consortium establishes rigorous energy efficiency standards for commercial and industrial LED lighting products. DLC Premium qualification ensures fixtures meet the highest performance criteria for utility rebate programs, while UL certification verifies that electrical components and safety systems comply with national safety standards for hazardous location equipment.

5 Year Warranty and Support

All our lights come with at least a 5-year warranty, and all warranty support is based in the USA. We take customer support seriously, and helping you with a warranty claim is important to us. Our experienced support team understands the importance of keeping your lighting operational and will work quickly to resolve any warranty issues.

Why Choose LED Lighting Supply for Your Paint Booth Project

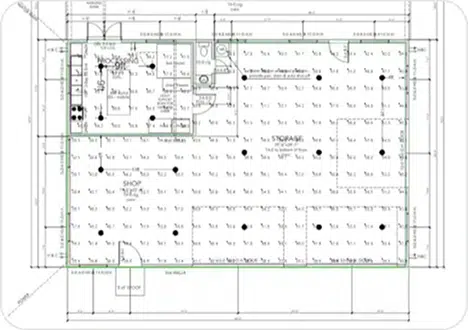

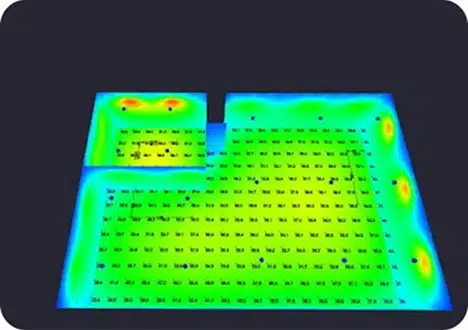

Our team creates complementary custom lighting layouts for your specific paint booth dimensions and application requirements. We calculate exact fixture placement to eliminate shadows and hot spots that compromise paint quality. Our experienced product specialists review your booth specifications and provide energy savings calculations that show your actual return on investment.

With over 17 years serving automotive and industrial painting facilities, we understand the critical safety requirements and performance standards your operation demands. We stock inventory in multiple warehouses nationwide to ensure fast delivery when you need fixtures quickly. Our extensive selection of products ensures we can meet any type of paint booth requirement, and placing an order is simple.

Common Mistakes and How to Avoid Them

I've seen these problems create serious safety violations and project delays in paint booth installations. Most of these mistakes stem from contractors trying to cut costs or not understanding the specific requirements for explosive atmospheres.

- Using standard vapor-proof fixtures instead of explosion-proof rated units. Check the nameplate for C1D1 or C1D2 certification before installation.

- Mounting fixtures directly above spray patterns where overspray builds up on lenses weekly. Position lights outside the direct spray zone and plan for regular cleaning access.

- Installing pendants without proper strain relief on the power cords. Use explosion-proof cord grips rated for the environment or you'll fail inspection.

- Sizing beam angles wrong for the ceiling height creates dark spots on the work surface. Narrow beams for high ceilings, wider spreads for standard height booths.

- Forgetting the emergency disconnect switch accessible from outside the booth. NEC requires it and inspectors will red-tag the job.

- Skipping photometric calculations and guessing fixture placement. Shadows and hot spots ruin paint jobs and customers notice immediately.

- Not coordinating fixture locations with the ventilation contractor. Lights interfering with airflow patterns create dead zones and overspray problems.

- Choosing low CRI fixtures to save money on color-critical work. Anything under CRI 80 makes color matching nearly impossible for automotive applications.

LED Lights for Paint Booths Frequently Asked Questions

What Safety Rating Do I Need for LED Paint Booth Lighting?

Class 1 Division 1 (C1D1) fixtures provide the safest approach for spray painting environments where explosive vapors exist during normal operations. Always confirm the exact hazardous area classification with your local fire marshal or Authority Having Jurisdiction before selecting fixtures. While Class 1 Division 2 fixtures cost less initially, C1D1 units undergo more rigorous testing and offer superior safety margins for active paint booth operations.

How Much Energy Can I Save by Switching to LED Paint Booth Lights?

Facilities typically reduce lighting energy costs by 60-75% when upgrading from metal halide systems. A 100-watt LED fixture replaces a 400-watt metal halide while delivering superior light output and eliminating ballast energy consumption. LED systems also operate significantly cooler, reducing HVAC load and creating more comfortable working conditions for painters.

What Light Levels Are Required for Different Paint Booth Applications?

General automotive painting requires 50-80 foot candles, while precision detail work needs 80-150 foot candles for optimal results. Paint inspection and quality control operations perform best with 100-150 foot candles to reveal surface imperfections and color variations. For booths with 10-12 foot ceilings, we recommend fixtures with 90-120 degree beam angles to achieve uniform coverage without shadows.

How Long Do LED Paint Booth Lights Typically Last?

Most explosion-proof LED installations run trouble-free for over 10 years with heavy daily use in paint booth environments. This eliminates the recurring expense and downtime of replacing metal halide bulbs every 6-12 months. We back our fixtures with a 5-year warranty and USA-based support to ensure long-term reliability for your operations.

What Color Temperature Is Best for Paint Booth Lighting?

Most customers prefer 5000K daylight for accurate color rendering and precise color matching work. Some facilities choose 4000K neutral white for warmer working conditions while maintaining excellent color accuracy. Both options provide CRI ratings above 70+ to reveal true paint colors without the yellow cast of sodium vapor or metal halide systems.

Can I Use Vapor-Proof Fixtures Instead of Explosion-Proof for Paint Booths?

Never substitute vapor-proof fixtures for explosion-proof requirements in paint booth applications. Vapor-proof fixtures protect against moisture and dust but lack the safety certifications necessary for explosive vapor environments. Only fixtures rated for Class 1 Division 1 or Division 2 meet the rigorous safety standards required for spray painting operations with volatile organic compounds.

What Certifications Should LED Paint Booth Lights Have?

Essential certifications include UL Listed, ETL Listed, and explosion-proof ratings for your specific hazardous location classification. DLC Premium certification ensures the highest efficiency standards and qualifies your project for maximum utility rebates. These certifications guarantee safety, performance, and energy efficiency while meeting insurance and code compliance requirements.

Why Should Electrical Contractors Choose LED Lighting Supply for Paint Booth Projects?

We provide complimentary custom lighting layouts that calculate exact fixture placement to eliminate shadows and hot spots that compromise paint quality. Our team leverages 15+ years of commercial and industrial project experience across 25,000+ completed installations to ensure proper safety compliance and optimal performance. We stock inventory in multiple warehouses nationwide for fast delivery and offer comprehensive technical support throughout your project.

What Mounting Options Are Available for Paint Booth LED Fixtures?

Mounting configurations include pendant, surface mount, and pole mount options depending on your booth design and ceiling height. Pendant mounting typically provides the most uniform light distribution across the work surface. Surface mounting works well for lower ceiling applications, while pole mounting offers flexibility for booths without suitable ceiling attachment points.

How Do LED Paint Booth Lights Handle High-Temperature Environments?

LED technology operates significantly cooler than metal halide systems, generating less heat while delivering superior illumination. Our explosion-proof LED fixtures are engineered to handle the temperature variations common in paint booth environments. The reduced heat output also decreases HVAC load and prevents temperature-related paint application issues that can affect finish quality.

What Voltage Options Are Available for Paint Booth LED Lighting?

Our explosion-proof LED systems feature integrated drivers that automatically adapt to 120-277V or 277-480V electrical systems. Installation connects seamlessly to existing circuits without additional transformers or voltage conversion equipment. This universal voltage compatibility simplifies installation and reduces project costs for electrical contractors working with different facility power configurations.