Showing 1–12 of 16 results

- SKU:LLS-G-HVLS-FAN-8FT-6B | Web ID:2625Availability:15 In StockShips 4-7 Days

- Diameter: 8 ft

- Speed: Variable

- Phase: 1P

- Color: Black

- Blade Material: Aluminum

- Controller: Wall Mounted VFD with Remote Control

- Blades: 6

- AMPs: 1.0 at 220V

- Frequency: 50/60Hz

- Fan CFM: 60,000

- Coverage Area: 2960 square feet

- RPM: 25-120

- Sound Level: <40 dBA

- Fan Weight: 47 lbs

- Motor Size: 800 Watts

- IP Rating: IP57

- Downrod: 39 Inches | Custom Available

- Mounting: I-Beam Standard

- Voltage: 208V-240V

- Warranty: Mechanical 15 years | Electrical 5

Starting At$5,270.91 - SKU:LLS-G-HVLS-FAN-10FT-6B | Web ID:2626Availability:12 In StockShips 4-7 Days

- Diameter: 10 ft

- Speed: Variable

- Phase: 1P

- Color: Black | Silver

- Blade Material: Aluminum

- Controller: Wall Mounted VFD with Remote Control

- Blades: 6

- AMPs: 1.3 A at 220V

- Frequency: 50/60Hz

- Fan CFM: 100,000

- Coverage Area: 3,230 square feet

- RPM: 25-110

- Sound Level: <40 dBA

- Fan Weight: 52 lbs

- Motor Size: 800 Watts

- IP Rating: IP57

- Downrod: 39 Inches | Custom Available

- Mounting: I-Beam Standard

- Voltage: 208V-240V

- Warranty: Mechanical 15 years | Electrical 5

Starting At$5,634.55 - SKU:LLS-G-HVLS-FAN-12FT-6B | Web ID:2623Availability:11 In StockShips 4-7 Days

- Diameter: 12 ft

- Speed: Variable

- Phase: 1P

- Color: Black | Silver

- Blade Material: Aluminum

- Controller: Wall Mounted VFD with Remote Control

- Blades: 6

- AMPs: 1.9 A at 220V

- Frequency: 50/60Hz

- Fan CFM: 125,000

- Coverage Area: 4,840 square feet

- RPM: 25-100

- Sound Level: <40 dBA

- Fan Weight: 55 lbs

- Motor Size: 800 Watts

- IP Rating: IP57

- Downrod: 39 Inches | Custom Available

- Mounting: I-Beam Standard

- Voltage: 208V-240V

- Warranty: Mechanical 15 years | Electrical 5

Starting At$5,998.18 - SKU:LLS-G-HVLS-FAN-14FT-5B | Web ID:2629Availability:8 In StockShips 4-7 Days

- Diameter: 14 ft

- Speed: Variable

- Phase: 1P

- Color: Black | Silver

- Blade Material: Aluminum

- Controller: Wall Mounted VFD with Remote Control

- Blades: 5

- AMPs: 1.28 A at 220V

- Frequency: 50/60Hz

- Fan CFM: 128,000

- Coverage Area: 4,865 square feet

- RPM: 25-75

- Sound Level: <40 dBA

- Fan Weight: 75 lbs

- Motor Size: 800 Watts

- IP Rating: IP57

- Downrod: 59 Inches Standard | Custom Available

- Mounting: I-Beam Standard

- Voltage: 208V-240V

- Warranty: Mechanical 15 years | Electrical 5

Starting At$7,089.09 - SKU:LLS-G-HVLS-FAN-16FT-5B | Web ID:2628Availability:8 In StockShips 4-7 Days

- Diameter: 16 ft

- Speed: Variable

- Phase: 1P

- Color: Black | Silver

- Blade Material: Aluminum

- Controller: Wall Mounted VFD with Remote Control

- Blades: 5

- AMPs: 2.0 A at 220V

- Frequency: 50/60Hz

- Fan CFM: 190,000

- Coverage Area: 7,500 square feet

- RPM: 25-75

- Sound Level: <40 dBA

- Fan Weight: 120 lbs

- Motor Size: 800 Watts

- IP Rating: IP57

- Downrod: 59 Inches Standard | Custom Available

- Mounting: I-Beam Standard

- Voltage: 208V-240V

- Warranty: Mechanical 15 years | Electrical 5

Starting At$7,452.73 - SKU:LLS-G-HVLS-FAN-20FT-5B | Web ID:2624Availability:12 In StockShips 4-7 Days

- Diameter: 20 ft

- Speed: Variable

- Phase: 1P

- Color: Black | Silver

- Blade Material: Aluminum

- Controller: Wall Mounted VFD with Remote Control

- Blades: 5

- AMPs: 2.8 A at 220V

- Frequency: 50/60Hz

- Fan CFM: 218,000

- Coverage Area: 10,760 square feet

- RPM: 25-60

- Sound Level: <40 dBA

- Fan Weight: 133 lbs

- Motor Size: 800 Watts

- IP Rating: IP57

- Downrod: 59 Inches Standard | Custom Available

- Mounting: I-Beam Standard

- Voltage: 208V-240V

- Warranty: Mechanical 15 years | Electrical 5

Starting At$7,816.36 - SKU:LLS-G-HVLS-FAN-24FT-5B | Web ID:2627Availability:5 In StockShips 4-7 Days

- Diameter: 24 ft

- Speed: Variable

- Phase: 1P

- Color: Black | Silver

- Blade Material: Aluminum

- Controller: Wall Mounted VFD with Remote Control

- Blades: 5

- AMPs: 3.8 A at 220V

- Frequency: 50/60Hz

- Fan CFM: 263,000

- Coverage Area: 14,000 square feet

- RPM: 25-55

- Sound Level: <40 dBA

- Fan Weight: 153 lbs

- Motor Size: 800 Watts

- IP Rating: IP57

- Downrod: 59 Inches Standard | Custom Available

- Mounting: I-Beam Standard

- Voltage: 208V-240V

- Warranty: Mechanical 15 years | Electrical 5

Starting At$8,180.00 - SKU:LLS-HVLS-FAN-10FT-6B | Web ID:2323Availability:20 In StockShips 3-4 weeks

- Diameter: 10 ft

- Speed: Variable

- Phase: 1P | 3P

- Color: Black

- Blade Material: Aluminum

- Controller: Wall Mounted VFD

- Blades: 6

- AMPs: 110-120V 1P 9.6A | 208-240V, 1P: 5.7A | 208-240V, 3P: 3.90A | 460-480V, 3P: 1.8A

- Frequency: 60 Hz

- Fan CFM: 15,000

- Coverage Area: 6,375 square feet

- RPM: 44

- Sound Level: <57 dBA

- Fan Weight: 95 lbs

- Motor Size: 0.5 HP

- Downrod: 1 ft, 2 ft, 3 ft, and 6 ft Extensions Available

- Mounting: I-Beam | Z-Purlins | Open Joist

- Voltage: 110V-120V | 208V-240V | 460V-480V

- Minimum Mounting Height: 10 Feet

- Minimum Ceiling Clearance: 5 Feet

- Minimum Horizontal Clearance: 2 Feet

- Warranty: 5 years

Starting At$5,731.67 - SKU:LLS-HVLS-FAN-12FT-6B | Web ID:2324Availability:20 In StockShips 3-4 weeks

- Diameter: 12 ft

- Speed: Variable

- Phase: 1P | 3P

- Color: Black

- Blade Material: Aluminum

- Controller: Wall Mounted VFD

- Blades: 6

- AMPs: 110-120V 1P 9.6A | 208-240V, 1P: 5.7A | 208-240V, 3P: 3.90A | 460-480V, 3P: 1.8A

- Frequency: 60 Hz

- Fan CFM: 36,500

- Coverage Area: 8500 square feet

- RPM: 44

- Sound Level: <57 dBA

- Fan Weight: 112 lbs

- Motor Size: 0.5 HP

- Downrod: 1 ft, 2 ft, 3 ft, and 6 ft Extensions Available

- Mounting: I-Beam | Z-Purlins | Open Joist

- Voltage: 110V-120V | 208V-240V | 460V-480V

- Min Mounting Height: 10 Feet

- Min Ceiling Clearance: 5 Feet

- Min Horizontal Clearance: 2 Feet

- Warranty: 5 years

Starting At$6,941.67 - SKU:LLS-HVLS-FAN-16FT-6B | Web ID:2325Availability:20 In StockShips 3-4 weeks

- Diameter: 16 ft

- Speed: Variable

- Phase: 1P | 3P

- Color: Black

- Blade Material: Aluminum

- Controller: Wall Mounted VFD

- Blades: 6

- AMPs: 110-120V 1P 9.6A | 208-240V, 1P: 5.7A | 208-240V, 3P: 3.90A | 460-480V, 3P: 1.8A

- Frequency: 60 Hz

- Fan CFM: 70000

- Coverage Area: 12,750 square feet

- RPM: 44

- Sound Level: <57 dBA

- Fan Weight: 126 lbs

- Motor Size: 0.5 HP

- Downrod: 1 ft, 2 ft, 3 ft, and 6 ft Extensions Available

- Mounting: I-Beam | Z-Purlins | Open Joist

- Voltage: 110V-120V | 208V-240V | 460V-480V

- Min Mounting Height: 10 Feet

- Min Ceiling Clearance: 6 Feet

- Min Horizontal Clearance: 2 Feet

- Warranty: 5 years

Starting At$8,273.33 - SKU:LLS-HVLS-FAN-20FT-6B | Web ID:2326Availability:20 In StockShips 3-4 weeks

- Diameter: 20 ft

- Speed: Variable

- Phase: 1P | 3P

- Color: Black

- Blade Material: Aluminum

- Controller: Wall Mounted VFD

- Blades: 6

- AMPs: 208-240V, 1P: 5.7A | 208-240V, 3P: 3.90A | 460-480V, 3P: 1.8A

- Frequency: 60 Hz

- Fan CFM: 137,000

- Coverage Area: 19,750 square feet

- RPM: 49

- Sound Level: <59 dBA

- Fan Weight: 197 lbs

- Motor Size: 1.5 HP

- Downrod: 1 ft, 2 ft, 3 ft, and 6 ft Extensions Available

- Mounting: I-Beam | Z-Purlins | Open Joist

- Voltage: 208V-240V | 460V-480V

- Min Mounting Height: 12 Feet

- Min Ceiling Clearance: 6 Feet

- Min Horizontal Clearance: 2 Feet

- Warranty: 5 years

Starting At$10,008.33 - SKU:LLS-HVLS-FAN-8FT-8B | Web ID:2322Availability:20 In StockShips 3-4 weeks

- Diameter: 8 ft

- Speed: Variable

- Phase: 1P | 3P

- Color: Brushed Aluminum | Black | Red | Yellow | Blue | White

- Blade Material: Aluminum

- Controller: Wall Mounted VFD

- Blades: 8

- AMPs: 208-240V, 3P: 1.90 A | 460-480V, 3P: 0.95 A

- Frequency: 60 Hz

- Fan CFM: 15,899

- Coverage Area: 4,250 Square Feet

- RPM: 44

- Sound Level: <57 dBA

- Fan Weight: 106 lbs

- Motor Size: 0.5 HP

- Downrod: 1 ft, 2 ft, 3 ft, and 6 ft Extensions Available

- Mounting: I-Beam | Z-Purlins | Open Joist

- Voltage: 110V-120V | 208V-240V | 460V-480V

- Min Mount Height: 10 Feet

- Min Ceiling Clearance: 3-4 Feet

- Min Horizontal Clearance: 2 Feet

- Warranty: 5 years

Starting At$6,904.22

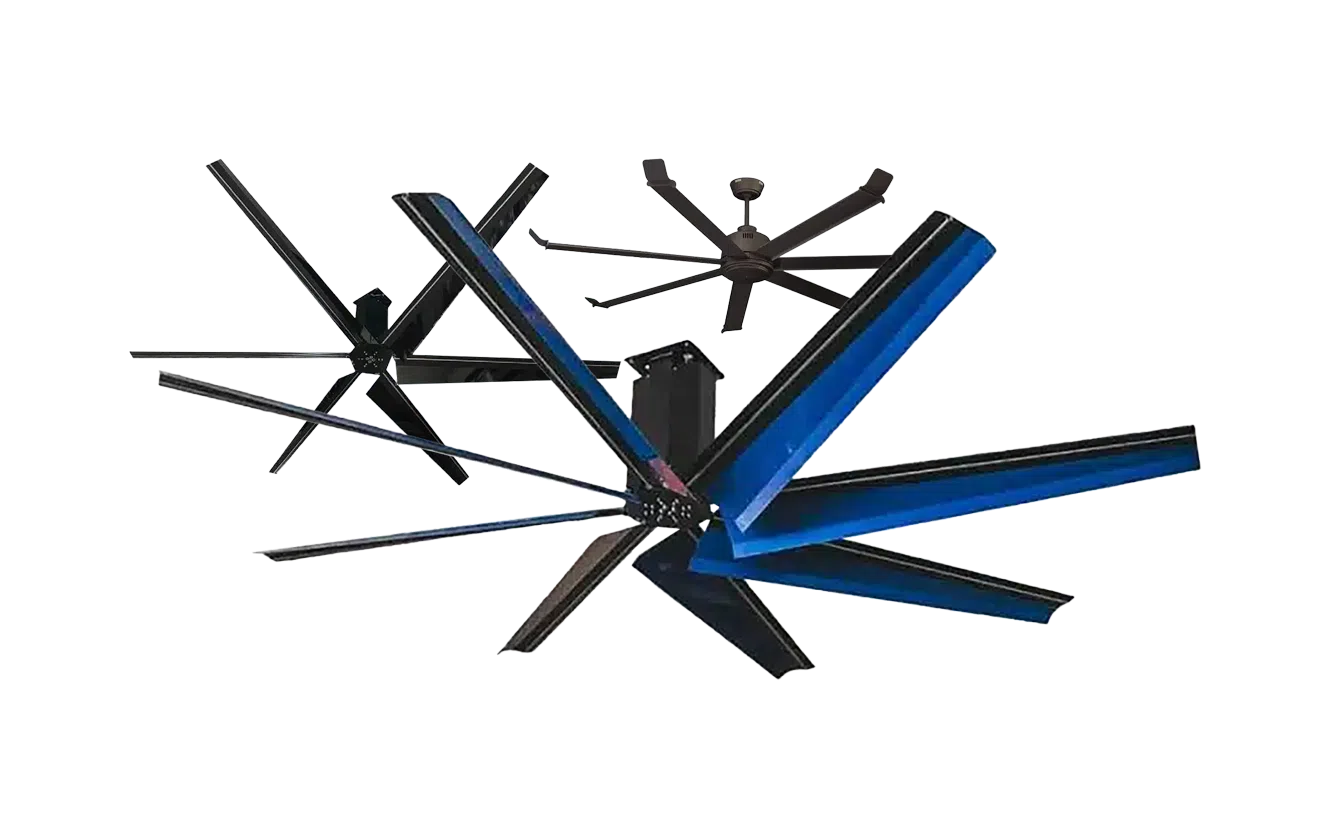

What are HVLS fans?

HVLS fans (High Volume Low Speed) are powerful, high-quality ceiling-mounted fans that reduce humidity, regulate air temperatures, and enhance air quality. Low-speed fans spin much slower while moving large volumes of air rapidly in enclosed areas. Our selection of HVLS ceiling fans includes tapered, longer-blade fans available in diameters up to 24 feet. The tapered, long blade engineering makes the elongated blades gradually thinner toward the end, equipping them with the ability to provide more consistent airflow by moving massive amounts of air.

What are the Benefits of Using HVLS Industrial Fans?

Create a more comfortable environment - HVLS industrial ceiling fans eliminate hot spots and stagnant air zones by creating a gentle breeze throughout your entire space. The large blade diameter produces a consistent breeze that makes workers feel 3-5 degrees cooler without cranking up the AC.

Energy savings - Most commercial installations consume only 1-3 kilowatts of electricity while delivering the air movement equivalent of dozens of small fans. You'll typically see 30-40% lower energy costs when using HVLS fans alongside your existing HVAC system.

The U.S. Department of Energy recognizes that proper air circulation systems can significantly reduce HVAC energy consumption in commercial facilities. According to DOE's industrial energy efficiency guidance, optimizing air movement systems is one of the most cost-effective strategies for reducing facility energy costs while maintaining worker comfort.

| Provide Summer Cooling | The powerful airflow creates an evaporative cooling effect on skin, allowing you to raise thermostat settings by several degrees while maintaining comfort. This approach works especially well in spaces where traditional AC systems struggle with coverage. |

| Winter Air Destratification | During colder months, reversing the fan direction recirculates heated air that naturally rises to the ceiling. This destratification process can reduce heating costs by up to 20% in high-ceiling facilities by redistributing warm air back to floor level, where workers need it. |

What are the Best Applications for HVLS Fans?

HVLS fans excel in commercial spaces with expansive open spaces where traditional HVAC systems can't efficiently regulate ambient temperatures. After seventeen years of helping customers in the commercial and industrial space, we've identified the key factors that determine success in each environment.

OSHA emphasizes the importance of maintaining proper ventilation and temperature control in industrial workplaces to ensure worker safety and productivity. The agency's heat exposure prevention guidelines specifically highlight how effective air circulation systems help prevent heat-related illnesses in manufacturing and warehouse environments.

| Warehouses | Improve air circulation and worker comfort while reducing heating and cooling costs. |

| Manufacturing Plants | Distribute air evenly across production floors to maintain consistent temperatures. |

| Distribution Centers | Enhance airflow in large open spaces to prevent hot and cold spots. |

| Gymnasiums | Keep athletes and spectators comfortable with better air movement and reduced humidity. |

| Airplane Hangars | Circulate large volumes of air to manage temperature and remove stagnant air pockets. |

| Agricultural Facilities | Maintain proper ventilation in barns, stables, and greenhouses for animal and crop health. |

| Automotive Service Bays | Move air efficiently in high-ceiling garages to improve comfort and ventilation. |

| Sports Facilities | Regulate airflow in arenas or indoor practice fields to enhance comfort and reduce HVAC load. |

| Retail Warehouses | Improve air movement and customer comfort in large, open retail spaces. |

| Cold Storage Areas | Eliminate temperature stratification and support efficient cooling system performance. |

| Event Centers | Maintain airflow and comfort for large crowds without excessive air conditioning costs. |

| Food Processing Plants | Control condensation and humidity while improving overall air quality. |

| Schools and Universities | Provide better airflow in gymnasiums, cafeterias, and large multipurpose areas. |

| Logistics Hubs | Support energy-efficient air circulation across loading docks and sorting areas. |

| Commercial Warehouses and Storage Facilities | Balance temperatures throughout large spaces for energy savings and comfort. |

Why Choose LED Lighting Supply for Your HVLS Fan Project

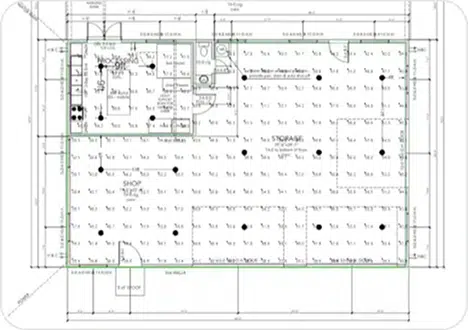

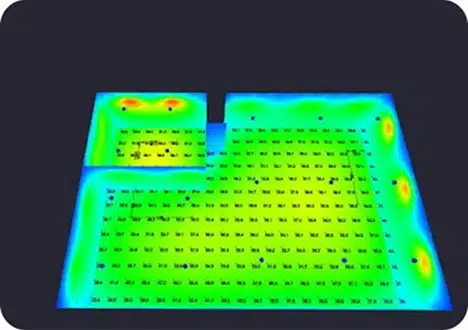

Our seventeen years of commercial and industrial application expertise mean we can provide specific energy savings calculations for your facility based on square footage, ceiling height, and current HVAC costs. Our product specialists have worked with thousands of industrial ceiling installations and understand the critical factors like mounting requirements, electrical specifications, and coverage patterns that determine project success.

We can provide complimentary custom airflow plans that show optimal fan placement for your specific space layout, eliminating the guesswork that leads to poor performance or costly mistakes. Unlike general equipment suppliers, we stock only commercial-grade industrial ceiling fans from manufacturers with proven track records in demanding industrial environments, backed by our technical support team that understands the unique challenges of high-volume air movement systems.

The Design Lights Consortium (DLC) provides technical requirements and energy efficiency standards for commercial air circulation systems. Their qualification requirements for energy-efficient equipment help facility managers identify systems that will deliver verified performance and energy savings in industrial applications.

Common Mistakes and How to Avoid Them

I've seen too many HVLS installations fail because contractors skip the fundamentals or facility managers get sold the wrong equipment. Most of these problems come down to poor planning and not understanding how these fans actually work in real environments.

- Mounting fans without proper structural analysis kills people. Get your PE to run the dynamic load calculations before you hang anything over 12 feet diameter.

- Spacing fans too close together creates turbulence and dead zones instead of smooth airflow. Keep them at least 1.5 times the blade diameter apart.

- Running them at full speed defeats the whole point of HVLS technology. Dial back to 60-70% max RPM for better coverage and lower energy costs.

- Installing without considering your existing HVAC patterns can short cycle your equipment or create pressure issues. Map your current airflows first.

- Buying undersized fans forces higher speeds and wastes energy. Size based on coverage area, not just what fits your budget.

- Forgetting about winter operation leaves money on the table. Set up seasonal controls to reverse direction for destratification.

- Installing fixed speed units limits your operational flexibility and energy savings potential. Variable speed drives pay for themselves in most commercial applications.

HVLS Fans | Industrial Ceiling Fans Frequently Asked Questions

What Size HVLS Fan Do I Need for My Facility?

Fan diameter depends on ceiling height and coverage area requirements. For standard warehouses with 20-25 foot ceilings, 16-20 foot diameter fans provide optimal coverage over 4,000-6,000 square feet each. Facilities with higher ceilings up to 40 feet can accommodate 24-foot diameter fans covering up to 8,000 square feet per unit.

How Much Energy Do HVLS Fans Actually Use?

Most commercial HVLS fans consume 1-3 kilowatts of electricity while providing airflow equivalent to 20-30 traditional ceiling fans. A typical 20-foot diameter fan uses approximately 2.5 kW at full speed, costing around $15-25 per month in electricity based on standard commercial rates.

What Installation Requirements Do HVLS Fans Have?

HVLS fans require structural mounting points rated for dynamic loads of 1,000-3,000 pounds depending on fan size. Most installations need 240V three-phase power and minimum ceiling heights of 14 feet for safety clearance. Professional structural analysis is required for installations in buildings not originally designed for large ceiling fans.

Can HVLS Fans Really Replace Air Conditioning Systems?

HVLS fans complement but don't replace AC systems, allowing thermostat settings 3-5 degrees higher while maintaining comfort through evaporative cooling effects. This approach typically reduces cooling costs by 30-40% in commercial facilities. The fans create air movement that makes occupants feel cooler without actually changing air temperature.

How Loud Are HVLS Fans During Operation?

Quality HVLS fans operate at 35-45 decibels at typical speeds, comparable to a quiet library environment. The large diameter and slow rotation speed (typically 60-200 RPM) eliminate the whooshing noise associated with smaller, high-speed fans. Variable speed controls allow adjustment based on noise sensitivity requirements.

What's the ROI Timeline for HVLS Fan Installation?

Most commercial installations see payback periods of 18-36 months through reduced HVAC operating costs. Facilities with high cooling loads or inefficient existing ventilation systems often achieve 12-18 month payback. Energy savings of $200-800 per fan annually are typical in industrial environments with 10+ hour daily operation.

Do HVLS Fans Work Effectively in Winter?

Reversible HVLS fans provide air destratification in winter by recirculating heated air from ceiling level back to occupied zones. This process can reduce heating costs by up to 20% in high-ceiling facilities where heated air naturally rises and becomes trapped. The gentle downward airflow redistributes warm air without creating uncomfortable drafts.

What Maintenance Do HVLS Fans Require?

Commercial HVLS fans need annual inspections of mounting hardware and quarterly cleaning of blade surfaces for optimal performance. Most quality units include permanently lubricated bearings requiring no routine maintenance for 10+ years. Professional inspection should verify structural mounting points and electrical connections annually.

How Do I Calculate the Number of HVLS Fans Needed?

Fan quantity depends on facility square footage, ceiling height, and air change requirements. A general guideline is one 20-foot diameter fan per 6,000-8,000 square feet in warehouses with standard ceiling heights. Our specialists provide complimentary coverage analysis using your facility dimensions and specific application requirements to determine optimal fan count and placement.

What Electrical Requirements Do Large HVLS Fans Have?

Most commercial HVLS fans require 240V three-phase power with dedicated 20-30 amp circuits depending on motor size. Fans over 20 feet typically need 480V power for efficient operation. Installation requires qualified electricians familiar with motor control circuits and variable frequency drives commonly used for speed control in commercial applications.