Showing 1–12 of 24 results

- SKU:MLLG-LED-HB3-200-50-120-[C] | Web ID:1952Black:1680 In StockShips 2-3 DaysWhite:146 In StockShips 2-3 Days

- Watts: 100 | 120 | 150 | 200

- Lumens: 14000 | 16800 | 21000 | 28000

- Lumens/Watt: 140

- Replaces: 250 | 400 Watt Metal Halide

- Color Temp: 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK08

- Voltage: 100V-277V

- Surge Protection: 4kV

- Operating Temp: -22°F to 122°F (-30°C to 50°C)

- Rated Life: 170,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Optics: Polycarbonate Lens

- Fixture Color: Black | White

- Mount: Eye-Hook (std) | Pendant

- Dimensions: 11.02 X 7.72 Inches

- Cord Length: 5 Feet

- Weight: 5.5 lbs

Starting At$99.72 - SKU:MLLG-LED-HB3-100-50-120 | Web ID:2024Availability:260 In StockShips 2-3 Days

- Watts: 60 | 80 | 100

- Lumens: 8400 | 11200 | 14000

- Lumens/Watt: 140

- Replaces: 150 | 250 Watt Metal Halide

- Color Temp: 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK08

- Voltage: 100V-277V

- Surge Protection: 4kV

- Operating Temp: -22°F to 122°F (-30°C to 50°C)

- Rated Life: 170,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Optics: Polycarbonate Lens

- Fixture Color: Black

- Mount: Eye-Hook (std) | Pendant

- Dimensions: 9.2 X 7.1 Inches

- Cord Length: 5 Feet

- Weight: 3.5 lbs

Starting At$82.99 - SKU:LLS-HB-200A-CC-[C] | Web ID:2574Black:1053 In StockShips 2-3 DaysWhite:604 In StockShips 2-3 Days

- Watts: 120 | 160 | 200

- Lumens: 19800 | 26400 | 33000

- Lumens/Watt: 165

- Replaces: 250 | 400 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK08

- Voltage: 100V-277V

- Surge Protection: 6kV

- Operating Temp: -22°F to 122°F (-30°C to 50°C)

- Rated Life: 134,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Optics: Polycarbonate Lens

- Fixture Color: Black | White

- Mount: Eye-Hook (std) | Pendant | Surface

- Dimensions: 11.8 X 6.6 Inches

- Weight: 5.1 lbs

Starting At$106.21 - SKU:MLLG-LED-HBC-200-5-120 | Web ID:1536Availability:70 In StockShips 2-3 Days

- Watts: 100 | 120 | 150 | 200

- Lumens: 15000 | 18000 | 22500 | 30000

- Lumens/Watt: 150

- Replaces: 250 | 400 Watt Metal Halide

- Color Temp: 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK08

- Voltage: 100V-277V

- Surge Protection: 6kV

- Operating Temp: -22°F to 122°F (-30°C to 50°C)

- Rated Life: 170,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Beam Angle (Opt): 60° | 90°

- Optics: Frosted Polycarbonate Lens

- Fixture Color: White

- Mount: Eye-Hook (std) | Pendant

- Dimensions: 10.7 X 7.3 Inches

- Cord Length: 5 Feet

- Weight: 8 lbs

Starting At$117.90 - SKU:MLLG-LED-HBHO-240-5-120 | Web ID:1528Availability:177 In StockShips 2-3 Days

- Watts: 150 | 175 | 200 | 240

- Lumens: 28500 | 33250 | 38000 | 45600

- Lumens/Watt: 190

- Replaces: 1000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK08

- Voltage: 100V-277V

- Surge Protection: 4kV

- Operating Temp: -22°F to 122°F (-30°C to 50°C)

- Rated Life: 134,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Beam Angle (Opt): 60° | 90°

- Optics: Polycarbonate Lens

- Fixture Color: Black

- Mount: Eye-Hook (std) | Pendant | Surface

- Dimensions: 14.7 X 7.32 Inches

- Cord Length: 5 Feet

- Weight: 12 lbs

Starting At$179.64 - SKU:MLLG-AG-LED-HB-300-5-120-[V] | Web ID:980100V-277V:194 In StockShips 2-3 Days277V-480V:259 In StockShips 2-3 Days

- Watts: 300

- Lumens: 45000

- Lumens/Watt: 150

- Replaces: 1000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 70+

- IP Rating: IP65

- IK Rating: IK08

- Voltage: 100V-277V | 277V-480V | 127-300VDC

- Operating Temp: -22°F to 140°F

- Rated Life: 164,000 (L70) hours

- Dimmable: 1-10V

- Beam Angle (Std): 120°

- Optics: Tempered Glass Lens

- Fixture Color: Black

- Mount: Eye-Hook (std) | Pendant | Surface

- Dimensions: 16 X 8 Inches

- Cord Length: 5 Feet

- Weight: 21 lbs

Starting At$353.15 - SKU:LLS-X-HB8-150/120/100-CC | Web ID:2188Availability:577 In StockShips 3-5 Days

- Watts: 100 | 120 | 150

- Lumens: 15000 | 18000 | 22500

- Lumens/Watt: 150

- Replaces: 250 | 400 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK10

- Voltage: 100V-277V

- Surge Protection: 4kV

- Operating Temp: -40°F to 113°F (-40°C to 45°C)

- Rated Life: 50,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 120°

- Optics: Polycarbonate Lens

- Fixture Color: Black

- Mount: Eye-Hook (std) | Surface

- Dimensions: 11.6 X 8 Inches

- Cord Length: 5 Feet

- Weight: 4.5 lbs

Starting At$128.69 - SKU:LLS-X-HB8-150-5-HV | Web ID:2187Availability:346 In StockShips 3-5 Days

- Watts: 150

- Lumens: 21700

- Lumens/Watt: 145

- Replaces: 400 | 1000 Watt Metal Halide

- Color Temp: 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK10

- Voltage: 277V-480V

- Surge Protection: 4kV

- Operating Temp: -40°F to 113°F (-40°C to 45°C)

- Rated Life: 50,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 120°

- Optics: Polycarbonate Lens

- Fixture Color: Black

- Mount: Eye-Hook (std) | Surface

- Dimensions: 11.6 X 8.5 Inches

- Cord Length: 5 Feet

- Weight: 10 lbs

Starting At$180.00 - SKU:LLS-X-HB8-240/200/180-CC | Web ID:2189Availability:606 In StockShips 2-3 Days

- Watts: 180 | 200 | 240

- Lumens: 27000 | 30000 | 36000

- Lumens/Watt: 150

- Replaces: 400 | 1000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK10

- Voltage: 100V-277V

- Surge Protection: 4kV

- Operating Temp: -40°F to 113°F (-40°C to 45°C)

- Rated Life: 50,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 120°

- Optics: Polycarbonate Lens

- Fixture Color: Black

- Mount: Eye-Hook (std) | Surface

- Dimensions: 12.8 X 8 Inches

- Cord Length: 5 Feet

- Weight: 6 lbs

Starting At$151.84 - SKU:LLS-X-HB8-240-5-HV | Web ID:2213Availability:20 In StockShips 3-5 Days

- Watts: 240

- Lumens: 36000

- Lumens/Watt: 150

- Replaces: 1000 Watt Metal Halide

- Color Temp: 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK10

- Voltage: 277V-480V

- Surge Protection: 4kV

- Operating Temp: -40°F to 113°F (-40°C to 45°C)

- Rated Life: 50,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 120°

- Optics: Polycarbonate Lens

- Fixture Color: Black

- Mount: Eye-Hook (std) | Pendant | Surface

- Dimensions: 12.8 X 9.1 Inches

- Cord Length: 5 Feet

- Weight: 8 lbs

Starting At$220.19 - SKU:LLS-X-HB8-310/270/240-CC | Web ID:2211Availability:607 In StockShips 3-5 Days

- Watts: 240 | 270 | 310

- Lumens: 34800 | 39150 | 45000

- Lumens/Watt: 145

- Replaces: 400 | 1000 Watt Metal Halide

- Color Temp: 4000K | 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK10

- Voltage: 100V-277V

- Surge Protection: 4kV

- Operating Temp: -40°F to 113°F (-40°C to 45°C)

- Rated Life: 50,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 110°

- Optics: Polycarbonate Lens

- Fixture Color: Black

- Mount: Eye-Hook (std) | Pendant | Surface

- Dimensions: 14 x 11 Inches

- Cord Length: 5 Feet

- Weight: 11 lbs

Starting At$189.44 - SKU:LLS-X-HB8-310-5-HV | Web ID:2214Availability:271 In StockShips 3-5 Days

- Watts: 310

- Lumens: 45000

- Lumens/Watt: 145

- Replaces: 1000 | 1500 Watt Metal Halide

- Color Temp: 5000K

- CRI: 80+

- IP Rating: IP65

- IK Rating: IK10

- Voltage: 277V-480V

- Surge Protection: 4kV

- Operating Temp: -40°F to 113°F (-40°C to 45°C)

- Rated Life: 50,000 (L70) hours

- Dimmable: 0-10V

- Beam Angle (Std): 120°

- Optics: Polycarbonate Lens

- Fixture Color: Black

- Mount: Eye-Hook (std) | Pendant | Surface

- Dimensions: 13.8 X 10.9 Inches

- Cord Length: 5 Feet

- Weight: 13 lbs

Starting At$246.15

What are LED Factory Lights?

Manufacturing environments demand lighting solutions far beyond standard commercial applications. Factory LED fixtures must withstand extreme conditions while delivering consistent, powerful illumination. Based on our 17 years serving industrial clients, we've learned that successful factory lighting requires robust construction, temperature resistance, and specialized ratings for hazardous environments. Some facilities need high-temperature lighting or explosion-proof lighting installed in hazardous areas. Our High Power and Robust LED Fixtures for Factories and Manufacturing Plants deliver:

- High lumen output with 60% energy savings over metal halide

- IK10 impact resistance for forklift and machinery environments

- IP65 waterproof rating for wash-down areas

- Operating range up to 302°F ambient temperature

- UL844 explosion-proof certification for hazardous locations

The U.S. Department of Energy's industrial lighting studies demonstrate that LED technology can reduce energy consumption by 50-90% compared to traditional high-intensity discharge lighting systems in manufacturing facilities. DOE's comprehensive analysis of LED benefits in industrial settings shows significant potential for cost savings and improved lighting quality across manufacturing environments.

Types of LED Factory Lights for Manufacturing Plants Use

Factory lighting selection depends entirely on your specific environment and operational requirements. Most manufacturing facilities benefit from one or more of these fixture categories:

| High Bays | LED UFO and Linear high bay LED lights replace Metal Halide, HID, and fluorescent systems with superior performance. UFOs handle the toughest conditions with waterproof construction, while linear fixtures seamlessly replace fluorescent strips with 120-degree beam angles. |

| Hazardous-Location | Never compromise safety in explosive environments. Our explosion proof lights meet rigorous UL844 testing standards and handle Class I, Division 1 and 2 locations. Standard LED fixtures can create dangerous situations in these environments. |

| High Temperature | Foundries, steel mills, and hot manufacturing processes require specialized high temp LED lights. We stock fixtures rated up to 302°F ambient temperature with specialized heat sinks and driver protection. |

NFPA 70, the National Electrical Code, establishes strict requirements for lighting equipment used in hazardous locations to prevent ignition of flammable gases, vapors, or combustible dusts. The NEC's hazardous location classifications define specific installation and equipment standards that must be followed in manufacturing environments where explosive atmospheres may be present.

What are the Benefits of Using LED Lights for Factories and Manufacturing Facilities?

| Dramatic Energy Reduction | Most industrial installations save 60-70% on monthly electricity costs. A typical 300-watt LED UFO replaces a 1000-watt metal halide while producing more usable light. |

| Superior Light Output | Our fixtures deliver up to 150 lumens per watt, creating brighter work environments with less power consumption. Workers report reduced eye strain and improved accuracy on detailed tasks. |

| Color Accuracy | Factory LEDs maintain CRI ratings above 70, allowing workers to distinguish wire colors, read labels clearly, and spot defects that poor lighting would hide. |

| Consistent Performance | Unlike metal halides that lose brightness over time, quality LEDs maintain 90% of initial output throughout their lifespan. No more gradually dimming work areas. |

| Maintenance-Free Operation | Running 12 hours daily, these fixtures operate for over 10 years without bulb changes or ballast replacements-eliminating scissor lifts, downtime, and labor costs. |

| Industrial-Grade Construction | Every fixture undergoes extensive quality testing before shipping. We provide comprehensive 5-year warranties with USA-based industrial lighting support. |

| Emergency Power Integration | Optional battery backup modules maintain illumination during power outages. Emergency systems work seamlessly with 0-10V dimming controls for code compliance. |

| Universal Voltage Compatibility | Auto-sensing drivers work with 100V-277V or 277V-480V systems without modification. Install directly into existing electrical infrastructure with no rewiring. |

| Smart Motion Detection | Integrated or add-on sensors reduce energy waste. Lights dim to 10% output when areas are unoccupied, then return to full brightness instantly when motion is detected. |

| Forklift-Proof Durability | IK10 impact ratings ensure fixtures survive machinery impacts and falling objects. Reinforced housings protect critical components in rugged industrial environments. |

| Flexible Installation | Choose from eyehooks, pendant mounts, trunnion brackets, or protective wire guards. All mounting systems support full fixture weight and enable quick installation. |

| Maximum Light Output | Our highest-output models generate 90,000+ lumens-ideal for 40+ foot ceilings and large-scale manufacturing environments. |

| Building Automation Ready | 0-10V dimming compatibility integrates with building automation systems for zoning, scheduling, and daylight harvesting. |

How Many Lumens Do You Need to Light a Factory?

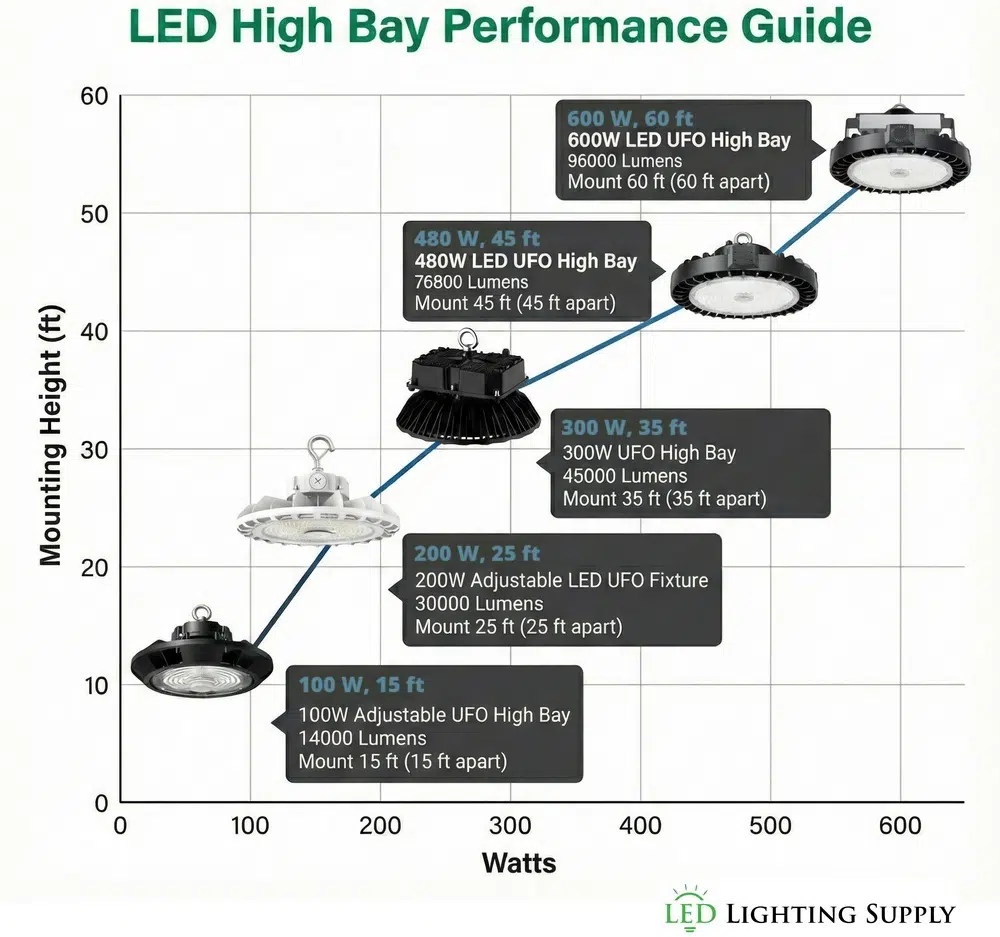

Proper factory lighting depends primarily on ceiling height and task requirements. We typically recommend these lumen ranges based on mounting height:

| 15–20 ft ceiling height | 100–150 watts producing 15,000–22,500 lumens per fixture |

| 20–30 ft ceiling height | 120–200 watts producing 18,000–30,000 lumens per fixture |

| 31–40 ft ceiling height | 240–300 watts producing 40,800–45,000 lumens per fixture |

| 40+ ft ceiling height | 400–600 watts producing 72,000–96,000 lumens per fixture |

OSHA, ANSI, and IES Foot Candle Requirements for Factory Lighting

Meeting regulatory lighting standards protects your workers and ensures compliance during inspections. OSHA establishes minimum requirements for factory environments:

| Offices and first-aid stations | 30 foot-candles minimum |

| General shops and construction plants | 10 foot-candles minimum |

| Warehouses, walkways, and corridors | 5 foot-candles minimum |

| Belowground work areas | 5 foot-candles minimum |

| Loading platforms and active storage | 3 foot-candles minimum |

ANSI and IES provide more detailed recommendations based on visual task requirements:

| Non-visual task areas | 10-20 foot-candles |

| Large-scale visual tasks with high contrast | 20-50 foot-candles |

| Small-scale visual tasks with medium contrast | 50-100 foot-candles |

| Very small-scale visual tasks with low contrast | 100-200 foot-candles |

OSHA's workplace lighting standards emphasize that adequate illumination is essential for maintaining safe working conditions and preventing workplace accidents. OSHA's construction industry lighting requirements establish minimum illumination levels for different work areas, while the Illuminating Engineering Society provides comprehensive recommended practices for industrial lighting design and implementation that go beyond basic safety requirements.

Safety and Performance Certifications

All our fixtures carry essential certifications, including DLC Premium, UL Listed, and ETL Listed approvals. These certifications ensure safety, performance, and energy efficiency while qualifying your project for utility rebates and tax incentives. DLC Premium certification guarantees the highest efficiency standards and maximum rebate eligibility.

The DesignLights Consortium establishes rigorous performance standards for LED lighting products to ensure maximum energy efficiency and utility rebate eligibility. DLC's Qualified Products List includes only lighting fixtures that meet strict photometric and electrical performance criteria, while Underwriters Laboratories provides comprehensive safety testing through UL's LED lighting certification programs to ensure products meet national safety standards.

5-Year Warranty and Warranty Support

All our lights come with at least a 5-year warranty, and all warranty support is based in the USA. We take customer support seriously, and helping you with a warranty claim is important to us. Our experienced support team understands the importance of keeping your lighting operational and will work quickly to resolve any warranty issues.

Expert Industrial Lighting Support and Custom Solutions

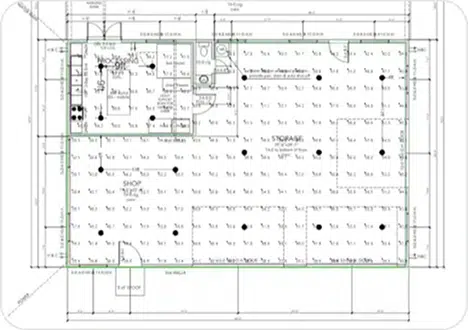

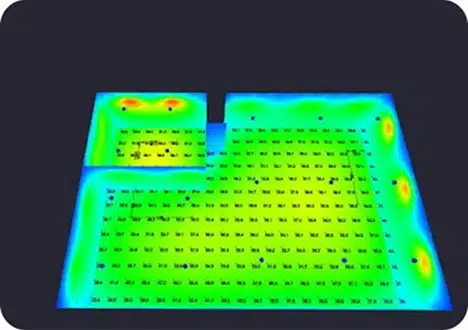

Our experienced product specialists have helped design lighting solutions for thousands of manufacturing facilities across every industry. We provide complimentary custom lighting plans that calculate exact fixture placement, energy savings, and return on investment for your specific facility. Our team understands complex industrial requirements including hazardous location classifications, temperature considerations, and OSHA compliance standards. Before you invest in new lighting, let our experts analyze your current energy usage and create precise savings calculations based on your local utility rates and operating schedule. We eliminate the guesswork by providing detailed photometric layouts that show exactly how your facility will look after the upgrade.

Common Mistakes and How to Avoid Them

Most factory lighting failures happen because installers don't match fixtures to their actual operating environment. These mistakes cost money, create safety hazards, and lead to premature failures.

- Using standard LED fixtures in hazardous locations without proper UL844 certification violates OSHA requirements and creates explosion risks. Check your Class and Division ratings before ordering anything.

- Installing fixtures rated for normal temperatures near furnaces or heat sources causes driver failures within months. High temperature fixtures cost more upfront but prevent costly callbacks.

- Mounting UFO high bays with narrow beam angles creates dark spots between fixtures. Wide beam angles work better for most factory applications with standard ceiling heights.

- Connecting fixtures to wrong voltage destroys drivers instantly and voids warranties. Double-check nameplate voltage against your electrical supply before energizing circuits.

- Skipping impact protection in forklift areas leads to expensive fixture damage and potential worker injuries. Wire guards and IK10 ratings prevent most impact damage.

- Installing fixtures without proper IP ratings in washdown areas allows moisture infiltration that kills electronics. IP65 minimum for any wet or humid environment.

- Using inadequate mounting hardware for heavy fixtures creates safety hazards when fixtures fall. Calculate total weight including mounting components and verify structural support.

- Over-lighting spaces wastes energy and creates glare problems for workers. Run photometric calculations to determine actual fixture quantities needed.

LED Lighting for Industrial Factories Frequently Asked Questions

What Wattage LED Factory Light Do I Need to Replace My 400W Metal Halide Fixture?

A 100-150 watt LED UFO high bay effectively replaces a 400W metal halide while producing more usable light. The LED delivers 15,000-22,500 lumens compared to the degraded output of aging metal halide systems. You'll achieve 60-70% energy savings with improved light quality and CRI ratings above 70 for better color accuracy.

How Long Do LED Factory Lights Last in 24/7 Manufacturing Operations?

Quality LED factory fixtures operate for 50,000+ hours while maintaining 90% of initial output. In continuous 24/7 operations, expect 5-6 years of maintenance-free performance before any noticeable light degradation. This eliminates the frequent bulb changes and ballast replacements required with metal halide systems running around the clock.

What IP Rating Do I Need for LED Factory Lights in Wash-Down Areas?

Manufacturing areas requiring regular cleaning or exposed to moisture need IP65 waterproof rated fixtures minimum. IP65 protection ensures complete dust-tight sealing and protection against water jets from any direction. For food processing or pharmaceutical facilities with aggressive cleaning protocols, consider IP66 rated fixtures for enhanced protection.

How Much Will LED Factory Lighting Save on My Monthly Electric Bill?

Most manufacturing facilities see 60-70% reduction in lighting energy costs after LED conversion. A typical facility replacing 50 metal halide fixtures saves $800-1,200 monthly depending on local utility rates and operating hours. The payback period typically ranges from 12-18 months when factoring in energy savings plus reduced maintenance costs.

Can LED Factory Lights Handle Forklift Impacts and Falling Objects?

Industrial LED fixtures with IK10 impact ratings withstand direct hits from forklifts, machinery, and falling objects without damage. The reinforced die-cast aluminum housing and impact-resistant polycarbonate lens protect critical LED components and drivers. This durability eliminates costly fixture replacements and safety hazards from broken lighting in high-traffic manufacturing areas.

What Temperature Range Can LED Factory Lights Operate In?

Standard industrial LED fixtures operate reliably from -40°F to +104°F ambient temperature. For foundries, steel mills, and high-heat manufacturing processes, specialized high-temperature LED lights function up to 302°F ambient temperature with enhanced heat sinks and driver protection. Always verify temperature ratings match your specific environment before installation.

Do I Need Special LED Lights for Hazardous Manufacturing Areas?

Class I, Division 1 and 2 locations require UL844 explosion-proof certified LED fixtures to prevent ignition of flammable gases or vapors. Standard LED lights create dangerous situations in these environments and violate safety codes. Explosion-proof fixtures feature reinforced housings and specialized sealing systems designed specifically for hazardous location requirements.

How Do I Calculate the Number of LED High Bays Needed for My Factory Floor?

Factory lighting calculations depend on ceiling height, desired foot-candle levels, and fixture lumen output. For 20-30 foot ceilings, space fixtures approximately 1.5 times the mounting height apart using 200-300 watt LED high bays. Professional photometric layouts ensure uniform light distribution and OSHA compliance while optimizing fixture quantities and placement.

Will LED Factory Lights Work with My Existing 480V Electrical System?

Most industrial LED fixtures feature auto-sensing drivers compatible with 277V-480V electrical systems without modification. Universal voltage capability allows direct installation into existing electrical infrastructure without rewiring or transformer changes. Verify voltage compatibility specifications before ordering to ensure seamless integration with your facility's power distribution.

Why Should Electrical Contractors Choose LED Lighting Supply for Factory Projects?

Our 15+ years of industrial lighting expertise and 25,000+ completed projects provide contractors with proven solutions and technical support beyond product sales. We offer complimentary photometric layouts, energy calculations, and specification assistance that help you win bids and ensure successful installations. Our 5-year USA-based warranty support protects your reputation with responsive service when issues arise.

How Does LED Lighting Supply Support Large Manufacturing Facility Upgrades?

We provide comprehensive project support including custom lighting design, energy savings analysis, and fixture staging for phased installations. Our consultative approach includes detailed ROI calculations based on your specific utility rates and operating schedules. With 25,000+ industrial projects completed, we understand complex requirements like hazardous location classifications, temperature considerations, and OSHA compliance standards.

Can LED Factory Lights Be Dimmed for Energy Savings During Low Production?

Most industrial LED fixtures include 0-10V dimming capability for integration with building automation systems or occupancy sensors. Fixtures can dim to 10% output during low-activity periods while maintaining instant full brightness when needed. Smart motion detection and daylight harvesting controls maximize energy savings without compromising safety or productivity in manufacturing environments.