Aircraft Hangar Lighting Plans | Aircraft Hangar Lighting Standards

Get Your Custom Lighting Plan With Product Recommendations

What to Expect When Requesting a Lighting Plan

Our Customers

Frequently Asked Questions

What Is Aircraft Hangar Lighting Design?

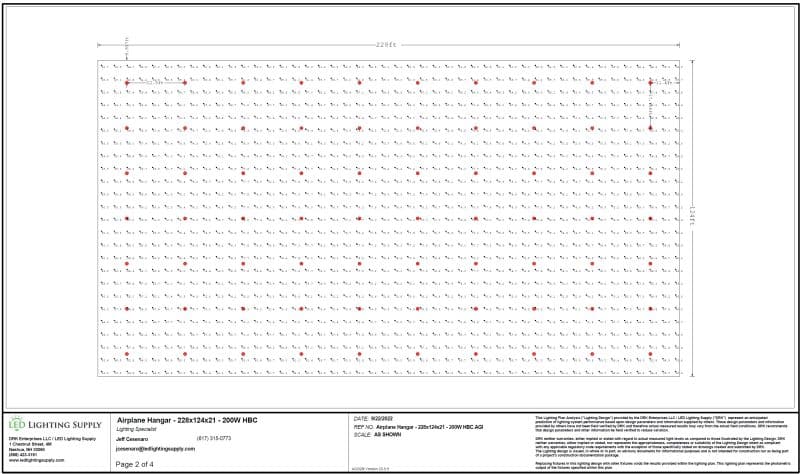

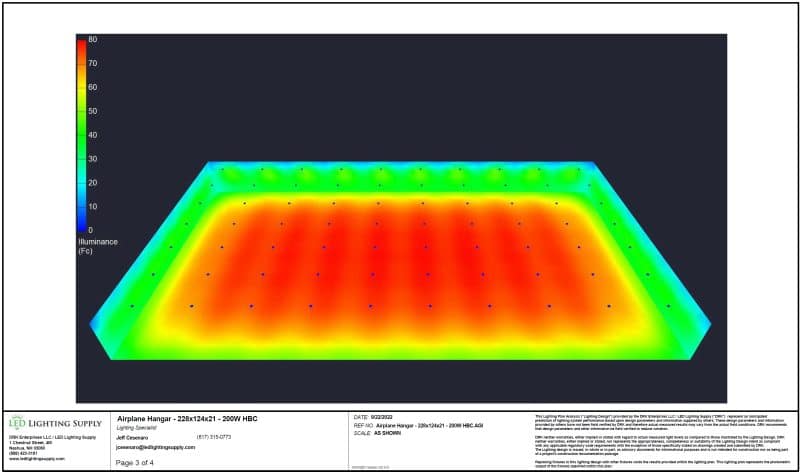

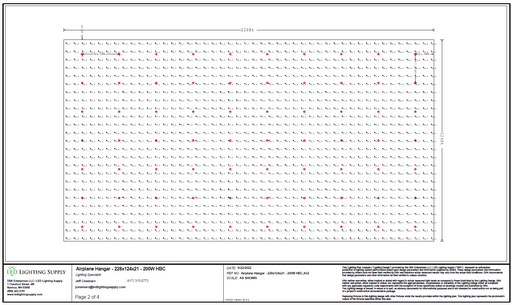

Aircraft hangar lighting design uses sophisticated software to model aircraft hangars and calculate optimal fixture placement for maintenance tasks. We determine the precise number of LED fixtures needed, their ideal locations, and ensure proper light balance across work areas. Converting from metal halide and HPS lamps to LED delivers exceptional energy efficiency, but proper design prevents poor uniformity and glare issues that plague many hangar retrofits. We provide free custom lighting designs for our commercial lighting and industrial lighting clients, electricians, contractors, and ESCOs.

What Are the Lighting Standards for Aircraft Hangars?

- General Work/Storage: 30 foot-candles

- Aircraft Maintenance: 30-50 foot-candles

- Detailed Maintenance Tasks: 70-100 foot-candles

- Drilling/Riveting/Fastening: 75 foot-candles

- Final Assembly: 100 foot-candles

- Inspection Work: 50-200 foot-candles

- Welding Operations: 50 foot-candles

High Bay Lights for Aircraft Hangars

100 / 120 / 150 / 200 Watt Adjustable High Bay

$99.72

Availability:1680 in Stock

150 / 175 / 200 / 240 Watt Adjustable LED UFO High Bay

$179.64

Availability:177 in Stock

120 / 160 / 200 Watt Adjustable UFO High Bay

$106.21

Availability:1053 in Stock

300 Watt UFO High Bay | 45000 Lumens

$353.15

Availability:194 in Stock

80 / 90 / 105 Watt Adjustable Linear LED High Bay

$143.27

Availability:353 in Stock

How Many Foot-Candles Do Aircraft Maintenance Hangars Need?

- Storage hangars require 30-50 foot-candles, while active maintenance facilities need 50-100 foot-candles, depending on task complexity.

- We recommend designing for dual-purpose use at 50 foot-candles to accommodate both storage and occasional maintenance work.

- Portable task lighting can supplement overhead fixtures for detailed work under wings and fuselage areas.

How Do You Reduce Glare in Hangar Lighting?

We specify acrylic domes or frosted lens covers on high bay fixtures to eliminate harsh LED dots and reduce direct glare. Ribbed optics and side shields control light distribution and minimize side glare. Proper mounting height optimization between 20-30 feet significantly reduces glare while maintaining uniform coverage.What Light Levels Are Needed for Aircraft Storage Only?

30-50 foot-candles provide adequate illumination for aircraft storage and basic movement operations. We recommend 50 foot-candles to allow flexibility for occasional maintenance tasks and ensure safe navigation around stored aircraft. This level meets OSHA requirements while accommodating future operational changes.Are Special Certifications Required for Hangar Lighting?

Fixtures must be UL Listed and rated for the hangar environment, but no aviation-specific certifications are required. We ensure all recommended fixtures meet commercial-grade standards suitable for aircraft maintenance facilities. Proper electrical code compliance and emergency lighting integration are essential for regulatory approval.

What Color Temperature Works Best for Aircraft Hangars?

4000K-5000K provides optimal color rendering for maintenance work while remaining comfortable for extended use. We specify fixtures with a minimum 70+ CRI to ensure accurate color representation for paint matching and component inspection. Higher color temperatures improve alertness and precision during detailed maintenance tasks without causing eye fatigue.How Much Can LED Conversion Save on Hangar Lighting Costs?

LED conversion typically delivers 60-70% energy savings compared to metal halide systems, plus dramatically reduced maintenance costs. Most hangars see 2-4 year payback periods with fixture lifespans exceeding 50,000 hours. LED Lighting Supply’s 15+ years of experience across 25,000+ commercial projects ensures optimal ROI through proper design and specification.Can Existing Hangar Fixtures Be Retrofitted to LED?

Many existing fixtures accommodate LED retrofit kits or lamp replacements, but complete fixture replacement often delivers better results. We evaluate current mounting points, electrical capacity, and light distribution requirements to recommend the most cost-effective approach. New LED fixtures provide superior light control and longer-term reliability compared to retrofit solutions.What Mounting Height Is Best for Hangar High Bay Lighting?

Most aircraft hangars require 20-40 foot mounting heights, depending on ceiling structure and aircraft size. We calculate optimal height based on beam angle, fixture spacing, and required foot-candle levels. Mounting too high reduces efficiency, while mounting too low creates shadows under aircraft wings and increases glare risk.

Do Aircraft Hangars Need Emergency Lighting Systems?

Building codes require emergency egress lighting and exit signs in all occupied aircraft hangars. We integrate battery backup systems or emergency generators to maintain minimum lighting during power outages. Emergency lighting must provide 1 foot-candle minimum along egress paths for safe evacuation around aircraft and equipment.How Do You Light Areas Under Aircraft Wings and Fuselage?

Strategic fixture placement and multi-directional lighting minimize shadows under aircraft components. We design with overlapping light patterns from multiple angles to reduce shadow zones. Portable work lights and under-wing lighting systems supplement overhead fixtures for detailed maintenance tasks requiring precise illumination.What Controls Are Recommended for Hangar Lighting Systems?

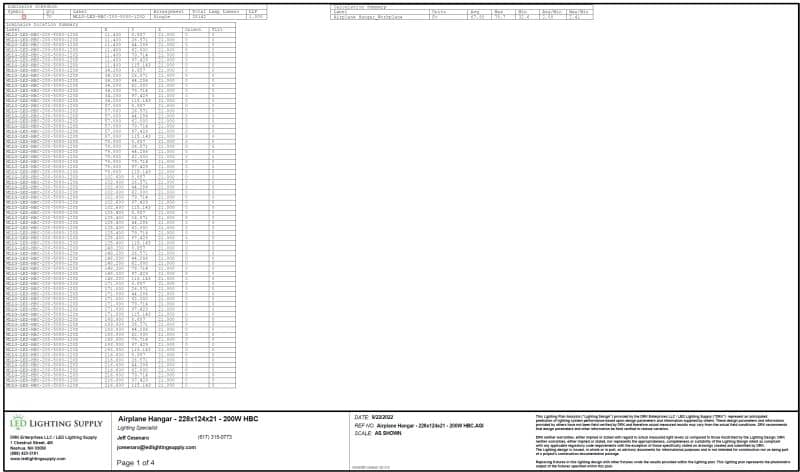

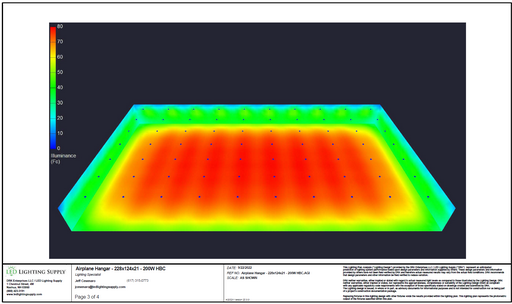

Zone switching allows the operation of only the required areas to maximize energy savings during limited use. Daylight harvesting controls automatically dim fixtures near overhead doors and skylights. Occupancy sensors work well in storage areas, while maintenance zones typically need manual switching for consistent lighting during extended work periods.Sample Hangar Lighting Plans and Heat Map