High Bay Lighting Plan

Get Your Custom Lighting Plan With Product Recommendations

What to Expect When Requesting a Lighting Plan

Our Customers

Frequently Asked Questions

What Is the Ideal High Bay Lighting Layout?

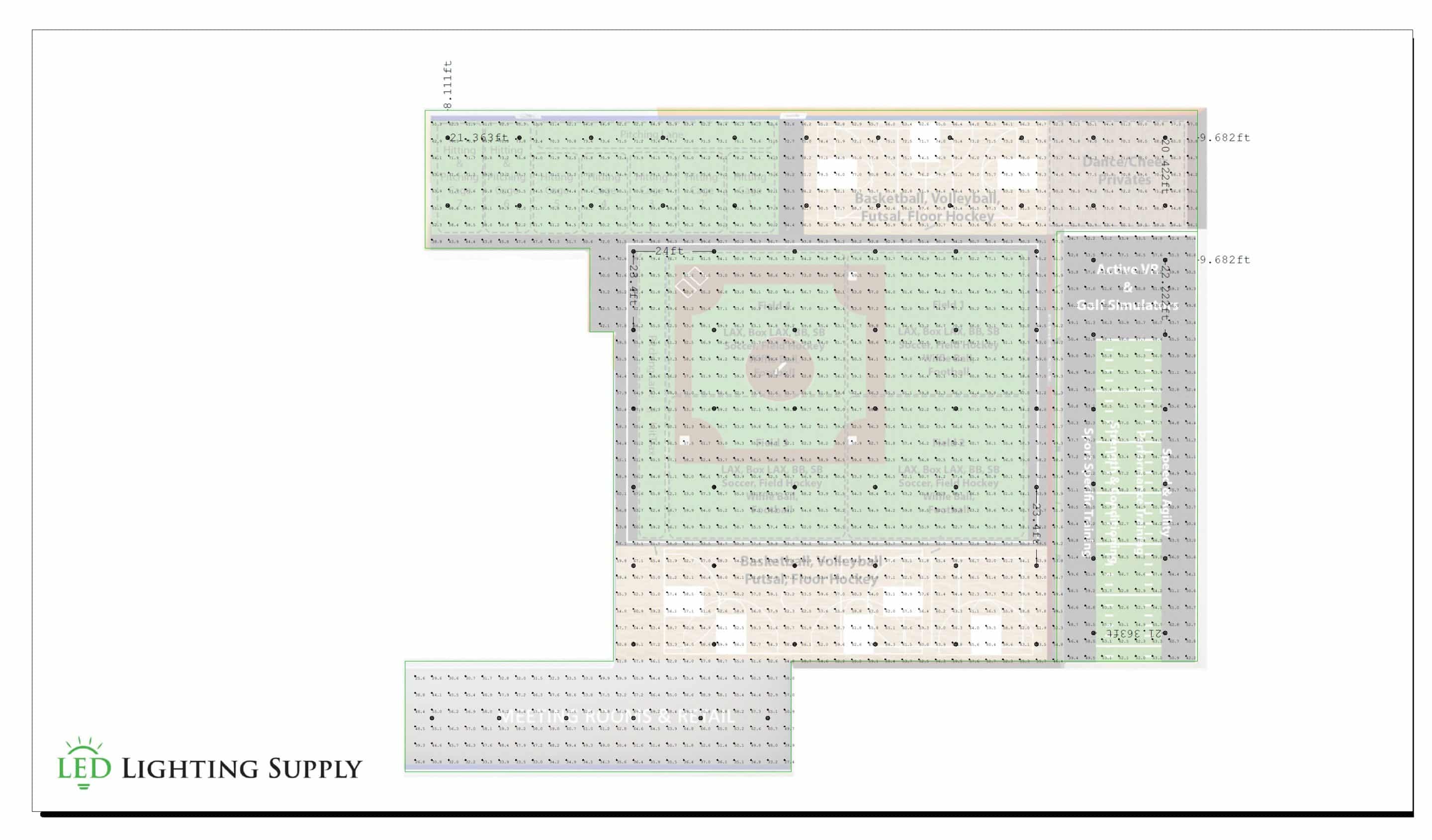

The ideal layout provides high bay fixture locations, light levels, and uniformity ratios across your space through a professional lighting plan. A lighting plan shows fixture types, foot-candle measurements, and balanced light distribution to eliminate guesswork for lighting upgrades and new installations.

How Do You Calculate High Bay Lighting Spacing?

Spacing varies by mounting height: 15-18 feet of spacing at 20 feet high, and 20-25 feet of spacing at 30 feet high, depending on the desired light levels. We create detailed lighting plans using photometric data and your space specifications (length, width, height) to determine optimal fixture spacing and achieve your target foot-candle requirements.

Best Sellers: LED High Bays

100 / 120 / 150 / 200 Watt Adjustable High Bay

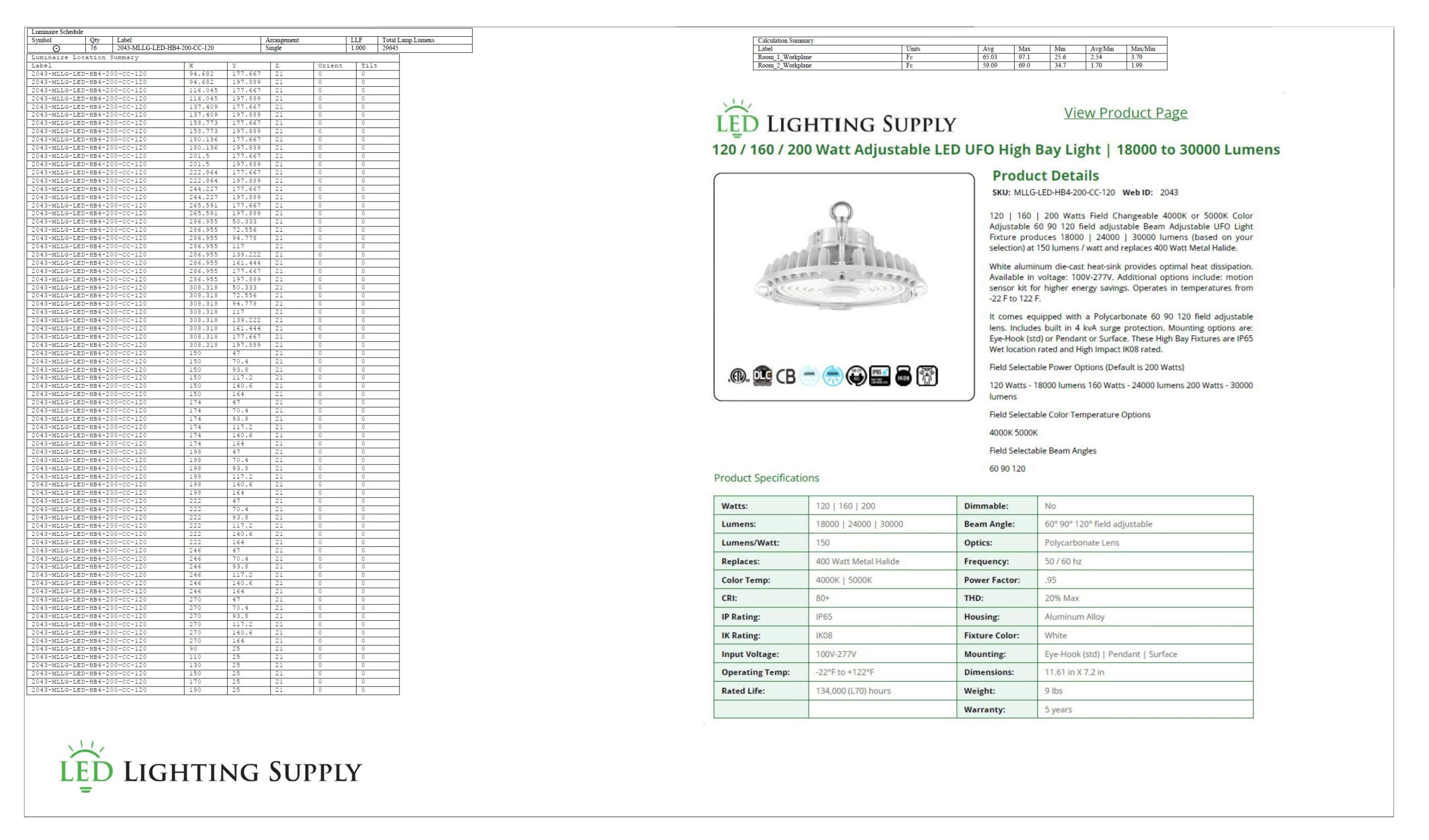

120 / 160 / 200 Watt Adjustable UFO High Bay

150 / 175 / 200 / 240 Watt Adjustable LED UFO High Bay

300 Watt UFO High Bay | 45000 Lumens

600 Watt UFO High Bay Light | 96000 Lumens | 5000K | 100-277V

How Many High Bay Fixtures Do I Need?

The exact number depends on your space dimensions, mounting height, and target light levels measured in foot-candles. We provide free lighting plans that calculate precise fixture quantities and placement locations, showing average, maximum, and minimum light measurements plus uniformity ratios across your facility.

Can You Create Lighting Designs for Any Size Facility?

Yes, facility size doesn’t impact our design capabilities. We’ve created lighting plans ranging from single fixture workshops to 1000+ fixture warehouses using the same professional photometric software and design standards for all commercial and industrial applications.

What Are the Risks of Using Only a High Bay Lighting Calculator?

Calculators provide rough fixture counts but lack photometric accuracy, spacing guidance, or uniformity analysis. Without proper light distribution data, you risk inadequate coverage, dark spots, or over-lighting that wastes energy and creates glare issues in your facility.

When Should You Get a Professional Lighting Design?

Before any LED conversion or new installation to ensure optimal performance and avoid costly mistakes. We provide free lighting plans to commercial and industrial end users, electricians, and contractors considering LED upgrades, virtually guaranteeing project success with our 15+ years of experience across 25K+ completed projects.

What Mounting Height Qualifies as High Bay Lighting?

High bay lighting is typically used in spaces with ceiling heights ranging from 15 to 40 feet. Below 15 feet requires low bay fixtures, while applications above 40 feet may need specialized very high bay or sports lighting solutions with enhanced optical control.

How Do Beam Angles Affect High Bay Performance?

Narrow beam angles (60-90°) work best for higher ceilings above 25 feet, while wide beam angles (120°+) suit lower mounting heights around 15-20 feet. Proper beam angle selection prevents over-spacing fixtures and ensures adequate light uniformity across your work area.

What Light Levels Do Different Industrial Applications Require?

General warehouse areas need 20-30 foot-candles, while detailed assembly work requires 50-100 foot-candles or higher. Manufacturing facilities typically target 30-50 foot-candles, depending on task requirements, with uniformity ratios maintained between 3:1 and 4:1 maximum.

How Much Can You Save Converting to LED High Bays?

Most facilities achieve 60-75% energy savings when replacing metal halide or fluorescent high bays with LED fixtures. Combined with reduced maintenance costs from 50,000+ hour lifespans, total operational savings typically provide 2-4 year payback periods depending on usage hours.

Sample High Bay Lighting Plan